The well pressure switch is a crucial component of a well water system, as it is responsible for controlling the operation of the well pump. This switch is designed to monitor the pressure in the water system and turn the pump on and off accordingly. When the pressure in the system drops below a certain point, the switch activates the pump to bring water into the system. Once the pressure reaches a predetermined level, the switch then shuts off the pump to prevent over-pressurization.

The well pressure switch typically consists of a diaphragm or bellows that responds to changes in pressure, as well as electrical contacts that open and close to control the pump. It is important to understand how the pressure switch functions in order to properly maintain and troubleshoot any issues that may arise. Without a functioning pressure switch, the well pump may run continuously, leading to increased energy consumption and potential damage to the pump and other system components.

In addition to controlling the pump, the pressure switch also serves as a safety mechanism to prevent the well system from running dry. If the water level in the well drops too low, the pressure switch will not be able to build up enough pressure to activate the pump, signaling that there is an issue with the water supply. Understanding the role of the pressure switch in the well system is essential for ensuring proper operation and preventing potential problems.

Key Takeaways

- The well pressure switch is a crucial component of a well water system that controls the water pressure.

- Regular inspection and maintenance of the pressure switch is important to ensure it functions properly.

- Testing the pressure switch can help identify any issues with the water pressure and the switch itself.

- Adjusting the pressure settings may be necessary to maintain the desired water pressure in the system.

- If the pressure switch needs to be replaced, it is important to follow proper procedures and safety precautions.

Regular Inspection and Maintenance

Regular inspection and maintenance of the well pressure switch are essential for ensuring the proper functioning of the well water system. Over time, the contacts in the pressure switch can become corroded or worn, leading to erratic operation or failure to activate the pump. Additionally, debris or sediment can accumulate in the diaphragm or bellows, affecting its ability to accurately sense pressure changes.

During routine maintenance, it is important to visually inspect the pressure switch for any signs of corrosion, damage, or wear. The electrical contacts should be checked for pitting or burning, which can indicate arcing and poor connection. The diaphragm or bellows should be inspected for any signs of damage or blockage that could affect its responsiveness to pressure changes.

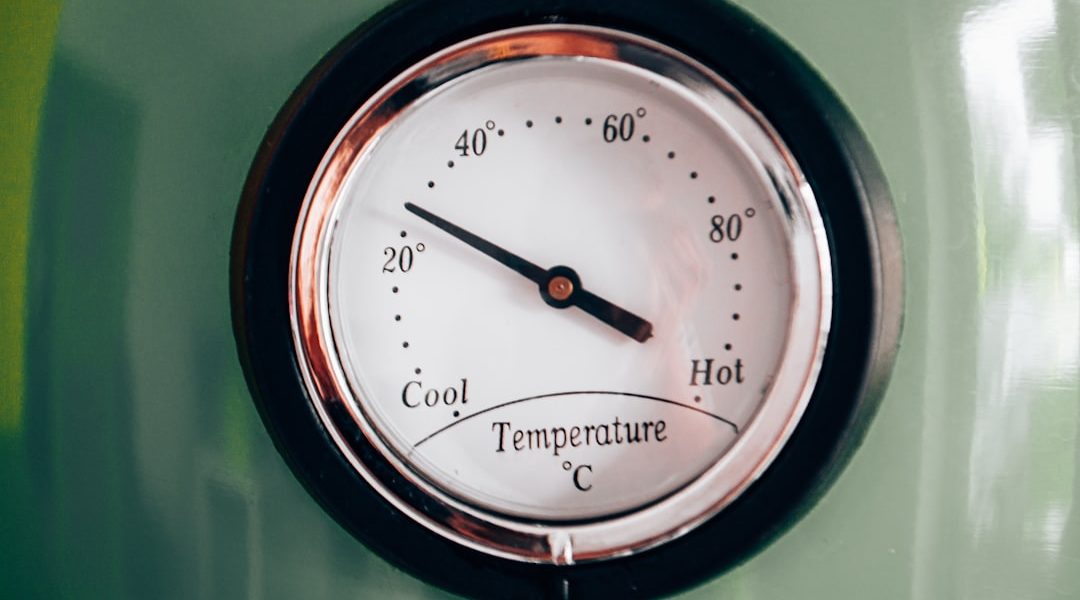

In addition to visual inspection, it is recommended to test the pressure switch periodically to ensure that it is functioning within the specified parameters. This can be done using a pressure gauge to measure the actual pressure in the system and compare it to the set points of the pressure switch. Any discrepancies should be addressed promptly to prevent potential issues with the well pump and water system.

Regular maintenance of the well pressure switch can help prevent unexpected failures and prolong the life of the well pump and other system components. By addressing any issues early on, homeowners can avoid costly repairs and ensure a reliable supply of water from their well system.

Testing the Pressure Switch

Testing the pressure switch is an important part of maintaining a well water system. By regularly testing the pressure switch, homeowners can ensure that it is functioning properly and adjust it as needed to maintain optimal water pressure in their home. There are several methods for testing the pressure switch, depending on the type of switch and the specific requirements of the well system.

One common method for testing the pressure switch is to use a pressure gauge to measure the actual pressure in the system and compare it to the set points of the pressure switch. This can be done by attaching a pressure gauge to a faucet or hose bib on the system and observing the pressure reading when the pump is running and when it shuts off. Any discrepancies between the actual pressure and the set points of the pressure switch should be addressed promptly.

Another method for testing the pressure switch is to use a multimeter to check for continuity in the electrical contacts. By disconnecting the power supply to the pressure switch and using a multimeter to test for continuity across the contacts, homeowners can determine if there are any issues with the electrical connections. If there is no continuity when there should be, it may indicate that the contacts are worn or corroded and need to be replaced.

Regular testing of the pressure switch can help homeowners identify any issues early on and prevent potential problems with their well water system. By understanding how to test the pressure switch and interpret the results, homeowners can ensure that their well pump operates efficiently and reliably.

Adjusting the Pressure Settings

| Pressure Setting | Before Adjustment | After Adjustment |

|---|---|---|

| Initial Pressure | 10 cmH2O | 8 cmH2O |

| Maximum Pressure | 20 cmH2O | 18 cmH2O |

| Minimum Pressure | 4 cmH2O | 6 cmH2O |

Adjusting the pressure settings of the well pressure switch may be necessary to maintain optimal water pressure in a home’s plumbing system. Over time, changes in water usage patterns or fluctuations in well water levels can affect the pressure requirements of a well system. By adjusting the pressure settings of the pressure switch, homeowners can ensure that their well pump operates at the appropriate pressures to meet their household’s needs.

To adjust the pressure settings of a well pressure switch, homeowners will need to locate the adjustment screws or nuts on the switch housing. These adjustment points are typically labeled for easy identification. By turning these screws or nuts, homeowners can increase or decrease the set points of the pressure switch to achieve their desired water pressure levels.

Before making any adjustments to the pressure settings, it is important to consult the manufacturer’s specifications for the pressure switch and well pump. These specifications will provide guidance on the recommended pressure ranges for optimal pump performance and system operation. By following these guidelines, homeowners can ensure that they do not exceed the capabilities of their well pump or compromise the safety and efficiency of their well water system.

Adjusting the pressure settings of a well pressure switch should be done carefully and methodically to avoid over-pressurizing or under-pressurizing the system. By making small adjustments and testing the system after each change, homeowners can fine-tune their well pump’s operation to meet their specific water pressure needs.

Replacing the Pressure Switch

In some cases, it may be necessary to replace a faulty or malfunctioning well pressure switch in order to restore proper operation of a well water system. Over time, wear and tear, corrosion, or electrical issues can affect the performance of a pressure switch, leading to erratic operation or failure to activate the well pump. When troubleshooting efforts fail to resolve these issues, replacing the pressure switch may be necessary.

To replace a well pressure switch, homeowners will need to first shut off power to the well pump at the electrical panel and drain any remaining water from the system. The old pressure switch can then be disconnected from the electrical supply and plumbing connections, allowing for removal from the system. It is important to take note of how the old pressure switch was connected in order to properly install the new one.

When selecting a replacement pressure switch, homeowners should ensure that it is compatible with their well pump and meets their specific water pressure requirements. It is recommended to consult with a professional or refer to manufacturer specifications for guidance on selecting an appropriate replacement switch.

Once a replacement pressure switch has been installed, homeowners should test the system to ensure that it operates within their desired pressure ranges and that there are no leaks or other issues with installation. By replacing a faulty pressure switch, homeowners can restore proper operation of their well water system and avoid potential damage to their well pump and other components.

Troubleshooting Common Issues

Troubleshooting common issues with a well pressure switch is an important part of maintaining a reliable supply of water from a well water system. There are several common issues that homeowners may encounter with their well pressure switches, including erratic operation, failure to activate, or continuous running of the well pump. By understanding how to troubleshoot these issues, homeowners can address them promptly and prevent potential damage to their well pump and other system components.

One common issue with well pressure switches is erratic operation, where the pump may turn on and off frequently or at irregular intervals. This can be caused by a variety of factors, including a faulty diaphragm or bellows, debris or sediment in the switch housing, or electrical issues with the contacts. By inspecting these components and testing for proper operation, homeowners can identify and address any issues that may be causing erratic operation.

Another common issue with well pressure switches is failure to activate, where the pump does not turn on when there is a demand for water in the system. This can be caused by low water levels in the well, a malfunctioning diaphragm or bellows, or electrical issues with the contacts. By testing for continuity in the electrical connections and ensuring that there are no obstructions in the switch housing, homeowners can troubleshoot this issue and make any necessary repairs.

Continuous running of the well pump is another common issue that may indicate a problem with the well pressure switch. This can be caused by over-pressurization of the system, a malfunctioning diaphragm or bellows, or electrical issues with the contacts. By adjusting the pressure settings of the pressure switch and testing for proper operation, homeowners can troubleshoot this issue and prevent potential damage to their well pump.

Hiring a Professional for Repairs

While many maintenance tasks for a well pressure switch can be performed by homeowners, there are certain repairs that may require professional assistance. For complex issues such as electrical problems with the contacts or internal components of the pressure switch, it is recommended to hire a qualified technician with experience in working on well water systems.

Professional technicians have specialized knowledge and tools for diagnosing and repairing issues with well pressure switches and other components of well water systems. They can accurately assess any problems with a pressure switch and make necessary repairs or replacements to restore proper operation of a well pump.

In addition to repairs, professional technicians can also provide valuable guidance on maintaining and optimizing a well water system for long-term reliability and efficiency. By consulting with a professional, homeowners can gain insight into best practices for maintaining their well pressure switches and preventing potential issues in the future.

When hiring a professional for repairs or maintenance of a well pressure switch, it is important to select a reputable and experienced technician who is familiar with working on well water systems. By entrusting these tasks to qualified professionals, homeowners can ensure that their well pumps operate reliably and efficiently for years to come.

It is also important to ask for references and to check the technician’s credentials and certifications. Additionally, homeowners should inquire about the technician’s experience specifically with well pressure switches and well water systems. By doing so, they can have peace of mind knowing that the technician is knowledgeable and capable of handling the job effectively. Ultimately, hiring a qualified professional for well pressure switch repairs and maintenance can save homeowners time, money, and potential headaches in the long run.

If you’re interested in learning more about well pressure switches, you should check out this article on how to troubleshoot common well pressure switch problems. This article provides valuable information on identifying and fixing issues with well pressure switches, helping you ensure that your well system is functioning properly.

FAQs

What is a well pressure switch?

A well pressure switch is a device that monitors the pressure in a well water system and controls the operation of the water pump. It is designed to turn the pump on when the pressure drops below a certain level and turn it off when the pressure reaches a preset upper limit.

How does a well pressure switch work?

The well pressure switch is typically installed near the water tank and is connected to the water pump. It contains a diaphragm or bellows that is sensitive to changes in water pressure. When the pressure drops below the set point, the switch activates the pump to start pumping water. Once the pressure reaches the upper limit, the switch turns off the pump.

What are the common issues with well pressure switches?

Common issues with well pressure switches include failure to turn on or off at the correct pressure, erratic cycling, and mechanical failure. These issues can be caused by a variety of factors such as waterlogged pressure tanks, clogged pressure sensors, or electrical problems.

How can I troubleshoot a well pressure switch?

To troubleshoot a well pressure switch, you can start by checking the pressure in the water tank, inspecting the switch for any visible damage, and testing the electrical connections. It is also important to check for any leaks in the system that could be affecting the pressure.

When should a well pressure switch be replaced?

A well pressure switch should be replaced if it is consistently failing to maintain the correct pressure levels, if it is damaged or corroded, or if it is more than 10 years old. Regular maintenance and inspection can help identify when a well pressure switch needs to be replaced.